TUNGSTEN CARBIDE BURRS

Our wide range of carbide burrs covers a variety shapes, offering optimal results in the preparation and removal of weld seams, bevelling and deburring in the shipbuilding, automotive, petrochemical, nuclear, foundry and aviation industries. Specially designed geometries meet the most demanding requirements in stainless steel, steel, cast steel, aluminium and composite applications providing fast stock removal and long service life with maximum efficiency.

Our innovative premium cutting types such as “Blue Power“, designed for very demanding applications in heavy industries such as shipbuilding, wind power or heavy metal industry, with a material removal capacity and duration never seen before, or our special cutting range for aluminium “Alu Tech” optimized with a special lubricant coating that generates less heat and reduces clogging, considerably extending the life of the tool, all of them manufactured with a studied handle joint, always guaranteeing safe work with low vibration levels and maximum performance.

Premium Cut

Blue Power

Blue Power high-performance rotary burrs are designed with optimized deep cross-cutting with a special geometry to carry out the most demanding applications. The tooth design allows for fast stock removal and excellent chip control with minimal vibration, even in hard materials.

Features:

- Special geometry with deep tooth design for increased tooth strength

- Longer tool life compared to the conventional rotary burrs of the market.

- Maximum stock removal on all types of steels, stainless steels, alloys etc.

Alu Tech

Alu Tech high-performance rotary burrs are optimized with a special lubricant coating that generates less heat and reduces clogging, considerably extending tool life, together with their studied extra thick tooth design reducing the cutting pressure required on all types of aluminium alloys.

Features:

- Special coating for smoother cutting and longer tool life

- Excellent chip removal on all types of aluminium alloys.

Inox Tech

Inox Tech high performance rotary burrs have been specially developed to adapt to the market needs in deburring applications of ferritic, austenitic and martensitic stainless steels.

Features:

- Cutting geometry designed specifically for stainless steels, reducing the heat input to the cutting edge of the tool and the workpiece.

- Excellent chip removal and reduced machining times.

Standard cut styles

Z-1 ALUMINIUM

For deburring soft materials such as aluminium alloys and plastics, extra thick tooth design to promote chip release without clogging.

Z-3

Standard teeth without chip breakers suitable for any type of steel, cast iron and general use, with good surface finishes.

Z-5

Fine teeth suitable for work on steels up to 65HRc where fine surface finishes are required.

Z-6

Universal double cut with chip breaker, fast material removal, creates a small chip reducing vibrations, resulting in a good surface finish

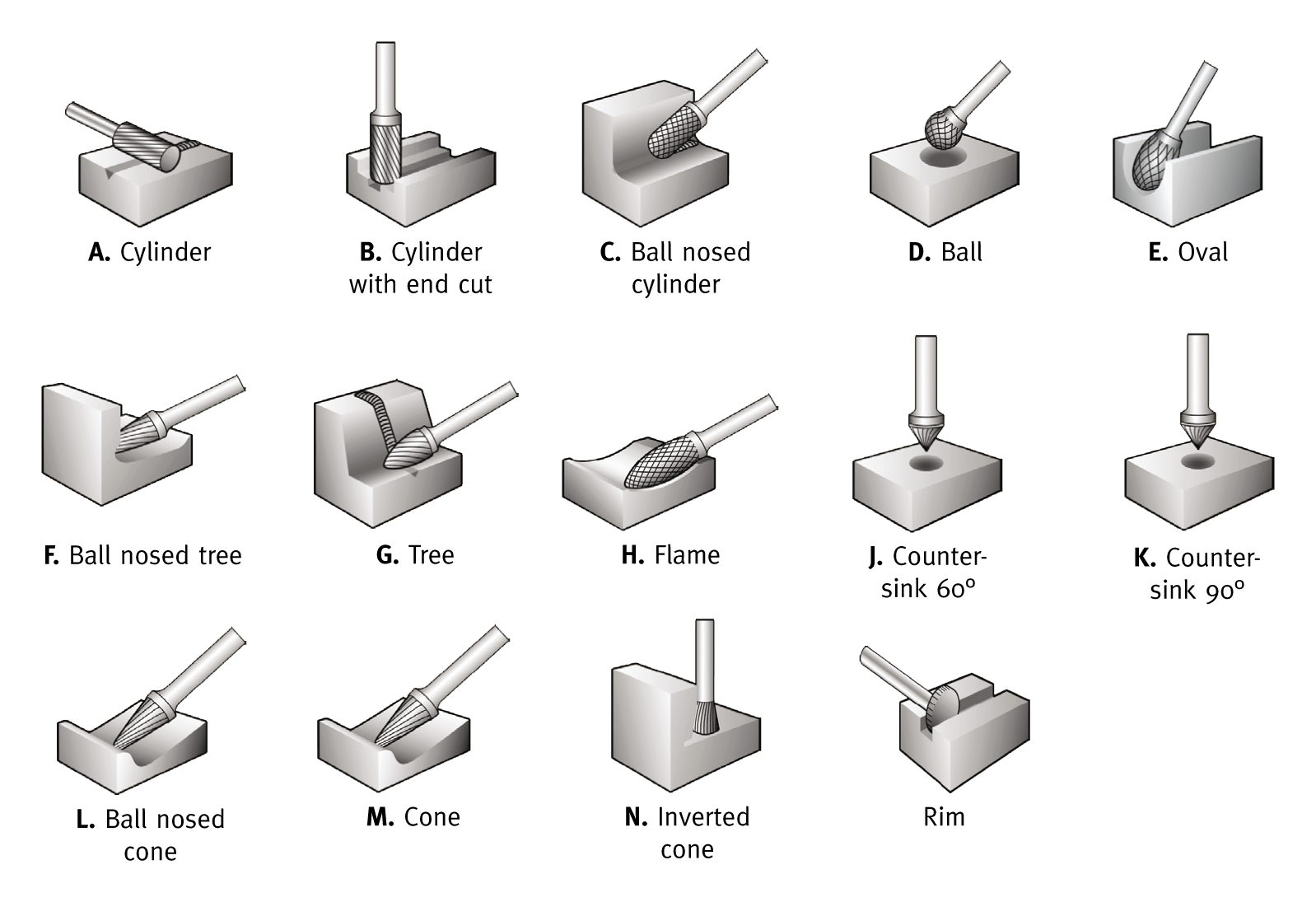

SHAPES